Dallas grew up round concrete and metal. Viaducts over the Trinity River, ramp braids around the Mixmaster, and a league of group overpasses raise a day-after-day load that will make most cities blush. These bridges are workhorses, now not museum portions, and so they demand a preservation technique that may keep tempo with warmness, freight visitors, hurricane cycles, and constant enlargement. Traditional inspection continues to be considered necessary, but it also misses opportunities: deferred tips, inconsistent measurements, and one-off footage that make yr-over-12 months comparisons more paintings than science. That is in which 3-d laser scanning offers a realistic soar.

This is just not approximately bright units, it's approximately building a dependable, repeatable report of a bridge’s condition and geometry. A 3D laser scanning carrier in Dallas offers vendors and engineers a aspect cloud they're able to degree on a Tuesday afternoon without sending a bucket truck into site visitors. It captures surfaces, clearances, alignments, and deformation with millimeter-stage precision throughout finished spans, not simply at chosen features. Done correct, scanning reshapes how we examine, plan, and prioritize upkeep.

What 3-d laser scanning genuinely delivers

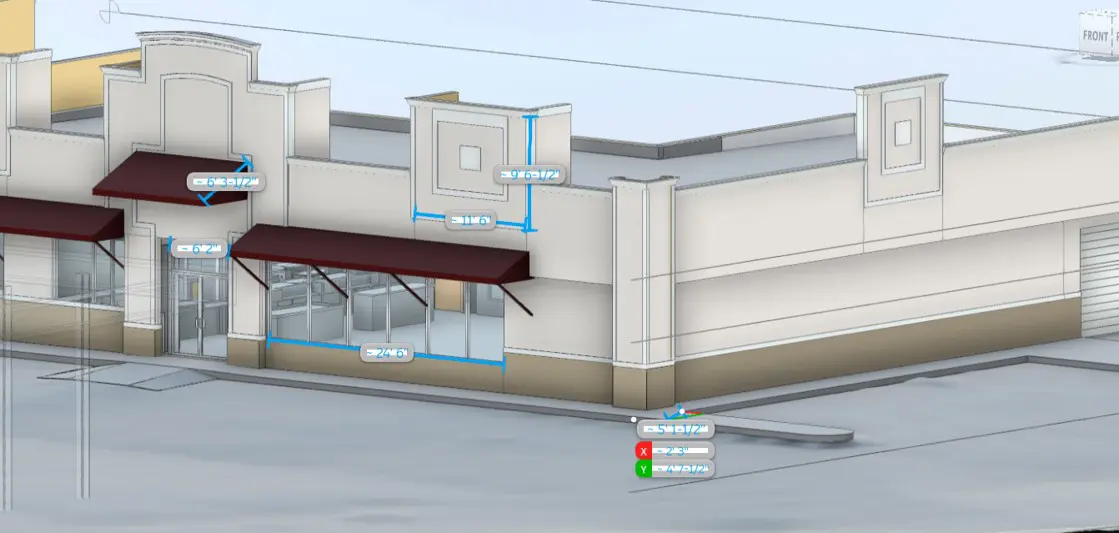

A terrestrial laser scanner emits pulses of gentle, measures the return time, and converts those returns right into a dense point cloud. Each level carries X, Y, Z coordinates and most often reflectivity. Register several scans at the same time as a result of survey manipulate and you get a unified, georeferenced sort of the bridge: deck, fascia girders, diaphragms, bearings, substructure, adjoining pavement, frame of mind slabs, overhead utilities, good-of-approach fences, even the crops that complicates get admission to. High-solution pics wrap the geometry with texture, so inspectors can click instantly from a crack inside the internet to an as-outfitted dimension.

On prevalent Dallas overpasses with concrete beams and cast-in-place decks, that you may anticipate element spacing from 3 to ten millimeters at a standoff of 10 to twenty-five meters. For trusses or tied arches with elaborate members, extra setups and tighter spacing help catch the lattice with out occlusion. The scanner sees what it should see, so making plans topics: to seize bearings tucked at the back of diaphragms, you need angles from each one abutment and below the growth joints if access permits. The payoff is a full electronic twin, not a stitched university of cellphone pix.

Why this concerns for Dallas bridges

Traffic counts store rising alongside I‑35E, I‑30, and US‑seventy five. Overnight closures are conceivable, however they come with heavy coordination and expense. Daytime lane drops create rolling bottlenecks that ripple from Oak Lawn to Deep Ellum. Laser scanning compresses the time on website and the footprint of labor. A two-individual crew can scan a customary 3-span overpass in several hours for the duration of off-height home windows, routinely with no visitors keep watch over if they may be able to function from sidewalks, shoulders, or medians with perfect safe practices measures. When a closure is unavoidable, a exact plan emerges: specific tripod areas, the quantity of setups, and the necessary duration per setup. No guessing.

Weather and warmth are other constants. Dallas summers bake bearings and joints. Scanners do not care approximately heat in the related way individuals do, despite the fact that we plan around thermal shimmer and reflective glare. Rain can scale down returns on smooth surfaces and complicate defense around slick decks. With planning, which you can shoot in the past morning time, whilst site visitors flows and temperatures are gentler, then conclude processing in the administrative center that afternoon. The schedule turns into a instrument instead of a hurdle.

From point cloud to insight

An unprocessed point cloud is raw info. The significance arrives whilst that tips lands throughout the workflows engineers already use. Registration device aligns scans to survey keep watch over and a time-honored coordinate machine, as a rule state plane North Central Texas. From there, deliverables department:

- A high-density point cloud, colorized by using intensity or photographic texture, precise for size and contrast. 2D drawings extracted from the cloud, which include elevations, sections at primary stations, and plan views with properly dimensions. three-D geometry, mainly as surfaces or simplified solids for BIM and CAD structures, tuned to the extent of detail a purchaser sincerely wants.

Those items give a boost to middle inspection duties. Deck condition mapping will become measurable in view that you may overlay chain drag and GPR zones on a geometric base. Girder camber and sweep will be measured at chords rather then guessed. Clearance to reside utilities can be checked in minutes devoid of lifting a tape close to energized strains. For groups monitoring situation over the years, the true vigour comes with repeat scans. You can go back a 12 months later, check in the recent dataset to the ancient, and compute differences. Subtle sag, payment at a unethical, or larger joint establishing will become quantifiable.

Field feel: what works and what journeys groups up

A Dallas corporation I labored with scanned a put up-tensioned container girder bridge over a creek susceptible to flash floods. The first try out overlooked the bottom soffit close to midspan on account that the workforce stayed high on the financial institution to dodge soggy ground. The factor cloud appeared suit until eventually the engineers attempted to research internet thickness and soffit geometry. The lesson changed into plain: for those who intend to research the container’s internal geometry from the exterior, you need tight spacing and long live times at low angles, preferably with a tripod established on a strong platform toward channel grade. The crew back with waders and a let to occupy the low-pass area, minimize occlusions by means of half of, and delivered a mannequin that supported tendon course validation.

Conversely, I even have obvious crews overdo it. They captured 400 million features on a honest two-lane overpass, spent days decimating the data, after which added a 40-gigabyte dataset to an inspection team that most effective necessary as-constructed clearances and bearing seats. Extra files is absolutely not free; it fees on-site time, exhausting force space, and patience. Scope your density to the choices at hand. If the need is clearances for a permit load, objective 5 to ten millimeter spacing close to soffits and 15 to 20 millimeter elsewhere. If the purpose is crack mapping on a pier, plan for closer scans and managed lights other than blanketing the whole thing with maximum choice.

Laser scanning isn't really a substitute for inspectors

Eyes, sense, and a hammer nevertheless earn their location. You shouldn't learn delamination through laser alone. A level cloud does not smell creosote, believe spongy picket blockading, or hear a hollow thud under chain drag. Instead, scanning complements these senses. It supplies context. When an inspector notes efflorescence at a joint, the experiment displays the joint geometry and the drainage route that feeds it. When the hammer finds a deck delam, the scan’s floor mannequin helps estimate overlay portions and phasing limits.

Every company has studies wherein portraits and handwritten stationing fell short. Interfaces among historic and new work are accepted culprits. A pier widened in the Nineties may range via just a few degrees from the fashioned alignment. Paper drawings hardly catch the nuance. The scan famous misalignments that explain distinctive bearing rotations or leaky joints, and it does so without recent coring or negative verification. The influence is fewer surprises all the way through construction.

Safety and site visitors manipulate realities

Bridge inspections customarily push crews into injury’s method. Snooper vehicles are precious however invasive. Hanging systems require rigging and time. three-D scanning reduces hours spent in dwell lanes and on slim bends. It does not do away with site visitors regulate, yet it shifts the ratio. Many Dallas municipalities allow short-period shoulder career with increase note and real signage. A scanner can live on a tripod in the back of a crash barrier at the same time the operator works from a secure offset, capturing the girder line the usage of a protracted-latitude setup. When we need to input a lane, the scanner’s well-known dwell time allows define the closure window. A 5-minute catch, a two-minute transfer, and a repeat at 3 positions equals a certainly defendable 25-minute single-lane closure. Small efficiencies like this upload up throughout a district.

Accuracy, handle, and the bounds of faith

Point clouds can lie once you allow them to. Reflective metal plates can ghost, glass can confuse the instrument, and long baselines can collect waft. Control fixes this. In Dallas, we greatly tie scans into nation airplane the use of both GNSS observations with corrections or well-known traverse tied to nearby monuments. Set ambitions on inflexible surfaces with a view to now not move in the time of the consultation. Re-become aware of a few pursuits after lunch to review for tripod agreement, incredibly in summer season whilst asphalt softens. If the bridge is long, smash the task into logical stations and demand on redundant scans at every one overlap. Outlier removal and registration residuals don't seem to be documents, they may be your guaranty.

As for accuracy claims, be truthful approximately what “millimeter” skill. The device perhaps in a position to sub-centimeter precision at brief differ, however factual-global setups carry tripod vibration from truck site visitors, atmospheric variability, and operator mistakes. For a deck profile obligatory for overlay layout, the useful vertical accuracy characteristically sits inside the 3 to 6 millimeter fluctuate after sound registration. For span deflection lower than load, you desire a managed try with constant backgrounds, synchronized setups, and quick distances. Handheld or mobilephone LiDAR has a spot for rapid context trap, yet it seldom matches the stableness and absolute accuracy of a tripod-dependent unit devoid of meticulous manage.

Integrating with other inspection methods

A unmarried device not often solutions every query. We oftentimes pair scanning with ground-penetrating radar for decks and with thermal imaging for floor delamination screening in the early morning when thermal gradients cooperate. Laser scanning grants the geometric base; GPR and IR fill in cloth habits. For metallic bridges, magnetic particle checking out on suspect welds and ultrasonic thickness measurements nonetheless rule for crack and section loss detection. The experiment enables you locate and revisit the precise spot, even months later, and supports document the surrounding geometry which could outcome tension concentrations.

Laser archives also ties straight into structural evaluation. Extract beam lines, degree absolutely girder spacing, and compare to plot units that can be incomplete or contradictory after decades of changes. The change between a 36‑inch and a 33‑inch spacing matters while checking distribution aspects. Bearing seat elevations and rotations should be would becould very well be measured from the cloud to diagnose unintentional fixity or frozen bearings. I actually have noticed engineers notice that a supposedly growth bearing had comfortably turned into mounted resulting from asphalt creep against a keeper plate, whatever thing that footage hinted at however the element cloud validated with geometry.

Planning a 3-d laser scanning effort in Dallas

Budget, agenda, and deliverables ought to be agreed earlier than all people unpacks a tripod. Good groups front-load the task definition and treat scope creep as a threat to regulate, no longer a characteristic to include. When I scope a three-D Laser Scanning Service Dallas contract, I holiday the verbal exchange into several choices.

- What selections will the tips make stronger? Clearance tests for oversize rather a lot, overlay design, bearing substitute, load ranking updates, scour monitoring, or a baseline situation fashion. What level of accuracy is rather required? If you desire plus or minus five millimeters on the bearings, say so. If 15 millimeters is acceptable for favourite geometry, do no longer overpay for density one could no longer use. How will the consumer consume the tips? Native point cloud for in-space CAD, 2D sheets, or a simplified 3-d sort incorporated right into a BIM platform. Match the structure to the workforce’s abilities and instrument. What get right of entry to constraints exist? Night work, railroad coordination, environmental permits close to waterways, or defense regulations round crucial infrastructure. How customarily will you rescan? A baseline with annual or biennial updates supports details-pushed repairs, however solely if the period and investment are realistic.

That stage of clarity keeps quotes sane and expectations aligned. It additionally facilitates prioritize what to scan at high constancy and what to catch at context stage.

The Dallas twist: significant warmness, big skies, and large projects

Local context influences area craft. Summer heat waves produce mirage-like shimmer that could degrade returns over water or sizzling concrete. Early morning scanning basically yields purifier archives and better portraits. Stormwater routine fill creeks briefly; agenda soffit captures outdoor of flash flood season when plausible. Long sightlines around freeways are a blessing, however they invite https://www.pinterest.com/realityimtincdallas/ formidable setups that extend the scanner’s triumphant diversity. Resist the temptation to shoot every thing from one lofty perch. Move nearer, shorten baselines, lessen occlusions, and advance registration quality.

Dallas also runs on teamwork. Coordinating with TxDOT districts, city public works, railroads, and utilities demands clear documentation and predictable schedules. A 3-D Laser Scanning Dallas service who often navigates those channels will circulation speedier and with fewer surprises. Permit offices care about wherein tripods sit as plenty as wherein snoopers swing. A safety plan that bills for solar publicity, visitors buffers, and swift takedown strategies makes container days smoother and shortens all people’s learning curve.

Construction support and as-builts

Scanning earns its stay in the course of construction. Pre-pour deck scans offer elevation baselines for camber and deflection monitoring. Post-pour scans test journey high quality and thickness. For bearing rehabilitations, a scan of the existing seats and sole plates supports the fabricator deliver shim packs minimize to useful tolerances, now not generic estimates. After steel maintenance, a faster rescan files final geometry with more effective fidelity than redlined PDFs. When a contractor asks for a change order primarily based on unforeseen geometry, the cloud serves as an independent witness.

Contractors respect whilst the scan guides potential and approaches. Sequence planning profits precision whilst clearances and obstructions are measurable. You can plan crane placement with fewer surprises. If a area splice must thread among diaphragms, that you could confirm it truely beforehand lifting the metal. In congested city corridors, staging yards and haul routes benefit from context scans that embrace curbs, poles, and signal masts. These pragmatic wins traditionally promote the provider more than abstract claims approximately accuracy.

Change detection and long-term stewardship

The proper promise looks over years. Once you experiment a bridge, the marginal fee of rescanning drops. Crew familiarity improves. Control remains in position. With a constant workflow, you can still examine cloud to cloud, not simply draw to cloud. Differences start out. A two-millimeter net downward movement at midspan is likely to be noise, but 12 millimeters over two years calls for consideration. Settlement at an inclination indicates as a tilt inside the cap and a subtle rotation in bearings. Joints that open past layout less than seasonal cycles may also be tracked and correlated with temperature knowledge to differentiate thermal stream from structural glide.

In Dallas, where freeze-thaw is much less critical than in northern states, amendment usually stems from thermal cycling, heavy axle hundreds, and moisture-driven deterioration. Regular scanning catches deformation prior to it will become misery. It informs whilst to time table a complete NDT marketing campaign and while to continue. For companies stretched thin, that triage has true price.

Cost, ROI, and sincere limits

Cost varies with scope, access, and deliverables. For a small overpass with trouble-free get admission to, the all-in scanning expense probably reminiscent of a day of snooper paintings, generally less if visitors control is minimal. Larger, frustrating structures require more setups and greater place of work time. What counsel the balance is reuse. A experiment that helps inspection, design, and construction represents a couple of price range strains. Owners understand whilst one dataset serves 3 groups.

There are trustworthy limits. Heavy flowers underneath rural bridges can block sightlines except you clear a line or carry a boat for low angles. Highly reflective or very dark surfaces can call for exposure tweaks and additional passes. Water surfaces scatter the beam; you is not going to reliably version water beneath the soffit. And at the same time cellular mapping from a vehicle can trap long corridors rapidly, it should not but in shape the absolute accuracy and occlusion regulate of tripod-elegant scanning on most bridges, fairly around tight steelwork and bearings.

Selecting a 3-d Laser Scanning Service Dallas provider

Experience counts. Ask to determine uncooked point clouds, no longer just lovely renderings. Look for steady registration residuals, lean document leadership, and deliverables that match what your engineers will really use. Confirm that the crew understands bridges, no longer just constructions. Bearings, diaphragms, and girder naming conventions count number whenever you stream from geometry to judgements. Safety record and traffic handle making plans need to be part of the verbal exchange from the primary name.

Dallas has several able services, and the perfect of them collaborate good with inspectors and architects rather than treating scanning as a standalone product. They will ask approximately your load rankings, your known sizzling spots, and the exceptional questions you desire to reply. They will offer a dry run on a pilot span before you commit to a whole hall. They will communicate plainly about accuracy, limitations, and schedule negative aspects, and they can convey backup package as a result of disasters within the area do no longer await delivery.

A reasonable workflow that holds up

Over the earlier few years, a repeatable pattern has served proprietors and engineers in North Texas. It will never be glamorous, however it works.

- Pre-plan with a 30-minute table overview of drawings, previous inspection notes, site visitors volumes, and entry pictures. Mark preferred scan positions on a straight forward plan. Place transient manipulate and aims at sturdy, risk-free destinations formerly the key experiment. Check keep an eye on redundancy. Capture the bridge in a sequence of quick setups throughout off-height hours, prioritizing bearings, soffits, and severe clearances. Take website pics and notes for context. Register the documents the equal day, run QA on residuals, and bring a swift-appear excerpt to confirm policy cover previously demobilizing the site visitors regulate plan. Produce very last deliverables aligned to the judgements diagnosed at kickoff, with transparent metadata about accuracy, coordinate manner, and any conventional gaps.

That workflow assists in keeping surprises small and trust top. It also builds a library of method notes that make the second one and third scans speedier.

Where that's headed

Adoption in Dallas is progressively expanding from monstrous interchange tasks to municipal overpasses and waterway crossings. As organizations see the significance of yr-over-yr comparisons and production-capable context, scanning strikes from a uncommon carrier to a prevalent line object. Integration with asset management systems is recuperating, allowing level clouds and extracted capabilities to 3D Building Scanning Services sit beside inspection rankings and preservation histories. The info turns into no longer just a exceptionally image but a dwelling portion of the bridge’s checklist.

The subsequent features would be incremental as opposed to flashy. Better registration across long corridors. Smarter extraction of beneficial properties like cracks and spalls with human-in-the-loop verification. Tighter integration with structural diagnosis methods that accept as-built geometry without tedious redesigning. And extra disciplined rescan methods that treat the bridge not as a static object but as a dwelling format with a measurable heartbeat.

For Dallas, with its titanic site visitors and bigger objectives, this way matches. 3D Laser Scanning Dallas is not very a slogan, that's a concrete means to determine what you're operating with, to minimize risk, and to make bigger calls at the excellent time. Bridges respond well to that sort of cognizance. They gift it with fewer surprises, safer work zones, and longer carrier lives. And for these folks who have spent summer season mornings underneath the hum of tires on scorching concrete, a nicely-structured experiment that continues crews out of harm’s method is its very own quiet victory.