Sometimes the most costly surprises disguise in plain sight. A tilted column a fragment of an inch out of plumb, a slab that crowns within the heart, ductwork squeezed so tightly in a chase that it whistles. In the Dallas marketplace, the place schedules are swift, constructions are mammoth, and trades are stacked, those “little” unknowns can burn weeks and budgets. That is the distance three-D laser scanning fills. It does no longer just catch geometry, it exhibits stipulations you probably did no longer understand to ask about, early ample to behave.

I actually have walked a variety of downtown Dallas mechanical rooms with an engineer, a superintendent, and a tape degree, basically to identify after mobilization that a beam seat is lessen than the plans reveal or a pipe rack bows Reality IMT Inc in Texas simply satisfactory to warfare with new cable trays. The distinction between that gut-sinking second and a easy install normally comes right down to one component: having a legit, validated as-built. A three-D Laser Scanning Service Dallas teams have confidence can turn a area of query marks right into a unmarried, living supply of fact.

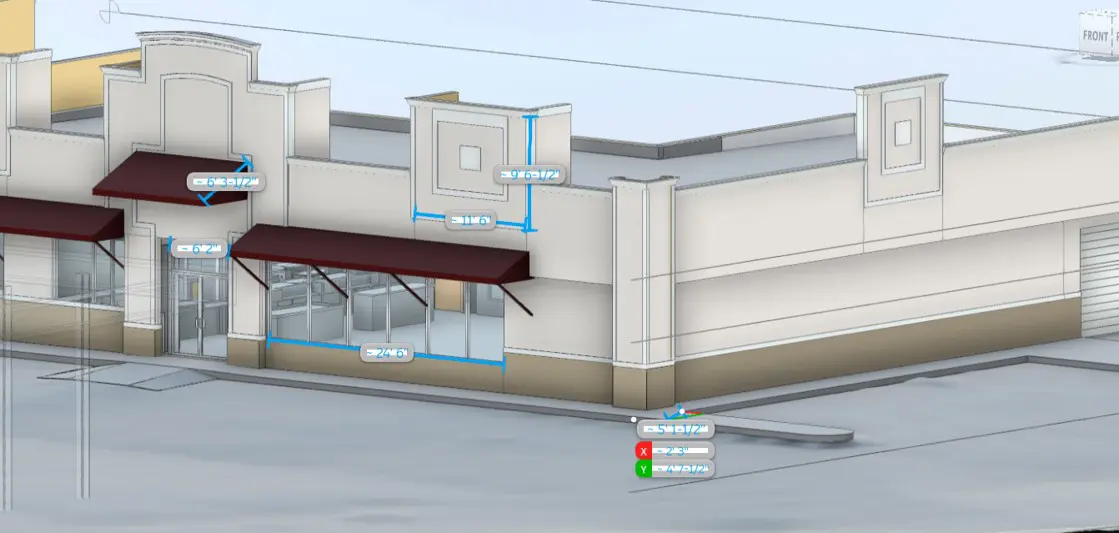

What 3-d laser scanning in actuality captures

At its core, 3-D laser scanning emits thousands and thousands of laser pulses to degree distances and angles to visible surfaces, building a dense “aspect cloud,” a virtual photograph of certainty. Modern terrestrial scanners acquire hundreds of thousands to tens of millions of issues consistent with 2nd. The sensible output is not really only a distinctly photograph, this is measurable statistics that you could part, query, and coordinate opposed to drawings or BIM versions.

Two technical factors rely for challenge effects. First, accuracy. Typical construction-grade scanning achieves 2 to four millimeters at 10 meters whilst the paintings is hooked up excellent with aims and handle. Second, insurance plan. Scans desire considerate station placement to determine round device, into corners, and across point variations. A speedy test from the entrance is rarely adequate. When we test occupied hospitals in North Texas, as an instance, we plan stations each and every 10 to twenty feet and catch overhead voids with tilted tripod heads. That density means less guesswork later.

The deliverables range. Some groups best want the uncooked point cloud. Others favor a registered, noisy-loose dataset aligned to a regular coordinate gadget, plus a Revit or AutoCAD edition of the main substances. The candy spot relies upon on your scope. If your trades will fashion their very own fabrication, the cloud is basically sufficient. If you desire to factor an updated CD set or prefabricate offsite, a disciplined, tolerance-tagged as-equipped edition is worth the added effort.

Dallas-special drivers for scanning

Dallas builds immediate. Projects smash flooring straight away, cling aggressive milestones, and push prefabrication to shave weeks off the vital path. That pace amplifies hazard from unknown prerequisites, relatively in 3 usual situations.

First, heavy renovations in favourite districts just like the Arts District, the Design District, and alongside McKinney Avenue. Buildings from the Nineteen Eighties and Nineteen Nineties had been incessantly equipped with info that do not fit today’s drawings or tolerances. A unmarried riser room it really is 6 inches narrower than proven can resolve an entire MEP series. With three-D Laser Scanning Dallas undertaking groups can affirm clearances, invert elevations, and beam soffits ahead of demolition submittals are even authorised.

Second, vertical expansions and rooftop paintings. Mechanical penthouses across Uptown and the Medical District are compact and crowded. Crane days are pricey, and the charge of misfitting rooftop metal or a new air handling unit could be five figures in lost time. Scanning the roof and adjoining parapets shall we teams look at various anchor features, reduce heights, and structural deflections earlier than the metallic save drawings are finalized.

Third, industrial and logistics services across the I-35 and I-20 corridors. These structures are monstrous, yet their tolerances don't seem to be supreme. Slabs can vary more than you believe over 500 feet. Racking, conveyors, and robot structures desire validated flooring and column grids. Laser scanning shortly identifies slab flatness and levelness deviations so device installers can shim strategically in place of find difficulties piecemeal.

From factor clouds to chance reduction

Real significance shows up while the info drives choices. In train, scanning reduces hazard in five approaches.

It identifies misalignments early. One downtown place of business retrofit confirmed a 1.75-inch offset between the structural grid inside the drawings and the actual columns, caused by lengthy-time period constructing settlement. Without the test, new demising partitions and glass frames could have arrived precut and fallacious. With it, the team adjusted wall layouts in the version and shifted the millwork equipment previously fabrication.

It proves slope and fall. A brewery conversion in Deep Ellum needed steady flooring slope to flooring drains. The test’s colorized elevation map showed diffused birdbaths alongside a 70-foot run. The concrete workforce used the map to plot a surgical grind and fill, and the plumbing team kept away from a rework order later.

It validates duct and pipe routing. In hospital renovations, overhead congestion is the invisible enemy. A experiment of an present ICU ceiling exposed a hidden cable tray nested above a pale cove. The tray used to be now not on any drawings as it have been brought for the time of a previous IT improve. The contractor rerouted a 10-inch duct by means of four inches within the sort and not at all needed to touch the ceiling after deploy.

It exams façade and envelope circumstances. On a top-rise reclad, a sequence of scans from a swing stage showed window mullions bowed outward via up to a quarter inch close to the 18th surface, probably with the aid of warmth and wind cycles. That documents educated gasket variety and caulking process, stopping leaks that might have proven up for the time of the first summer hurricane.

It presents defensible documentation. When a dispute arose approximately a structural beam allegedly hooked up out of stage at a warehouse near DFW Airport, the test information and management file established the beam met the specified tolerance. The dilemma shifted to the device installer’s bracket design, saving the GC from an unfair lower back rate.

The Dallas workflow that on the contrary works

There is a change between having a scanner and going for walks an effective 3-d Laser Scanning Service Dallas clientele can depend upon. The well suited results come from a chain that respects both discipline realities and digital deliverables.

We leap with a scoping walk. Thirty mins onsite with the superintendent and business leads pays for itself. You in finding the access constraints, the hours whilst scanning will not intervene with operations, and the one-of-a-kind facets that remember. In a production plant in Irving, let's say, a scoping stroll printed that weekend scans have been the best selection thanks to forklift visitors for the duration of the week. That small scheduling perception averted three aborted mobilizations.

Next, we set control. If the mission already has a survey management community, we tie into it. If not, we identify our own driving survey-grade ambitions and, when external visibility permits, GNSS for world alignment. On interiors with lengthy corridors and confined line of sight, we vicinity aims at intersections and use checkerboarding to take care of registration accuracy. Control is the quiet hero right here. Without it, clouds float and fashions do not overlay accurately with design, which defeats the intent.

Capture is available in passes. We disguise usual areas with primary density, then revisit vital corridors, mechanical shafts, and interfaces with increased selection and greater scanner positions. Tripod peak version improves line of sight into tight interstitial spaces. For some initiatives, exceedingly on rooftops with package, we increase terrestrial scans with hand-held SLAM units to fill gaps lower than louvers and among congested pipes.

Registration and QA are nonnegotiable. We run automatic registration first, then handbook assessments, and invariably produce a registration file with residuals and same old deviations. If the residuals exceed the tolerance agreed all the way through scoping, we rescan. It is more affordable to repair it then than to deceive the trades with a fantastically but reasonably unsuitable type.

Only after the cloud is sound can we type. We do no longer variety the whole lot, handiest what influences the scope. For an MEP-heavy venture, that suggests slab, construction, concrete beams, architectural partitions, leading duct and pipe 2 inches and bigger, cable trays, and any appliance or helps that could constrain routing. For a façade job, it way mullions, anchors, slab edges, and mounts. Everything else remains as a point cloud history to save expenditures targeted.

Finally, we integrate. Coordination conferences run bigger while the cloud is loaded into Navisworks or Revit alongside layout models. You can minimize sections at any place. Superintendents have fun with printed snapshots of troublesome spots, taped to the wall inside the trailer. Fabricators pull dimensions straight away from the variety, with a shared information of tolerance.

Hidden stipulations you are able to expect in older Dallas buildings

Over the final decade, various styles have emerged inside the metroplex. Knowing what tends to cover helps you select wherein scanning promises the maximum leverage.

Slab part wander. The drawings could convey a perfectly immediately slab side, however scans in most cases demonstrate a tender wave over long runs. Curtain wall anchors and waterproofing details desire to follow that fact otherwise you get inconsistent gaps and intricate flashing.

Stair stringer twist. In older place of work cores, stair stringers in certain cases twist a bit of, both from fashioned fabrication or long-time period stream. Finish carpenters hit upon it while handrails do not marry to partitions. A test and edition let you prefab brackets with matched offsets.

Existing MEP float. Legacy duct branches and copper lines seldom hold supreme angles after years of renovation. One Children’s Medical District mission had vacuum traces that drifted 1 to two stages off ninety at couplings. Scanning made that visual so the staff may possibly layout custom offsets rather than strength-are compatible simple elbows.

Out-of-plumb columns. It is minor in most structures, but even 1 / 4-inch over a story can nudge prefabricated wall panels out of tolerance whenever you do not plan for circulation joints or shim kits.

Lintel and header surprises. Masonry openings, principally in adaptive reuse warehouses, have erratically sized lintels. Heavy storefront applications have an understanding of that heads-up.

Accuracy and tolerance devoid of the mystique

The query I listen maximum: how desirable is the scan? The sincere solution is, accurate sufficient if the workflow is disciplined and the expectations are clear.

For primary format and coordination, a good-carried out experiment in Dallas conditions pretty much delivers 2 to 5 millimeters at 10 meters. That covers maximum MEP coordination and architectural are compatible-out. For gadget base plates, precision system, and façade panelization, you should be expecting a increased in style and a tighter management community, regularly supplemented with total station shots to key good points.

The larger lure is absolutely not uncooked accuracy, this is alignment. If your experiment shouldn't be accurately tied to the assignment coordinate technique, the mannequin will glance suitable in isolation but be wrong relative to layout. When we furnish 3D Laser Scanning Service Dallas clients can drop immediately into their BIM, we come with a coordinate record and ensure alignment by overlaying popular design positive factors and checking offsets in live periods with the design group. That 5-minute assessment saves headaches later.

Cost, schedule, and the ROI conversation

Scanning isn't really unfastened, and it deserve to no longer be used mindlessly. The communique about magnitude wants to be grounded in scope and probability. As a ballpark, small inside scans with registration could run inside the low thousands of bucks, even as multi-ground, variation-competent as-builts can reach into the tens of hundreds and hundreds, based on extent and modeling granularity. If you listen a charge some distance below that, ask what is incorporated and the way accuracy is tested.

Where the ROI turns into noticeable is in prefabrication and time table compression. A single evaded rework on a mechanical riser will pay for the experiment various occasions over. On a current lab in good shape-out in Richardson, the staff prefabricated one hundred twenty toes of 6-inch stainless runs structured on a scan-aligned type. Time kept onsite: kind of eight working days, hard work redeployed to some other surface, and 0 more healthy-up cuts. That is a fresh, defensible payback.

Scanning additionally shines when owner turnover is shut. Owners in North Texas are increasingly more savvy approximately electronic twins and asset archives. Delivering a level cloud and edition tagged with appliance IDs elevates the handover kit. It is just not glamorous, however while a facility engineer can degree between two valves in the cloud earlier ordering a replacement, that have confidence can pay off.

Integrating scans into BIM and container layout

Once you could have the cloud, use it. A incredible range of teams fee a scan, be given start, then let the dossier sit down. Make it portion of the working adaptation. Load the element cloud into Revit, run a normal deviation colour map opposed to design geometry to look in which construction diverges, and annotate difficult clashes and tight tolerances for discipline crews.

For layout, pairing the experiment with a robotic entire station is strong. You can extract elements from the variation that mirror the truly-international alignment and lay out anchors and sleeves with self belief. One concrete contractor in Plano now insists on a rapid experiment of embeds after placement. If an embed shifted all through vibration, they capture it although the concrete remains green enough to restoration.

On the flip part, be wary of over-modeling. Turning each pipe hanger into a sturdy slows the brand and provides expense with little gain. The aspect cloud already gives context. Model handiest the components that have an affect on routing, fabrication, or procuring.

Safety and scanning in stay environments

Construction and occupied centers current risks to each crews and the records capture task. In hospitals, you can want irritation handle allows and poor air setups if ceiling tiles are lifted to seize plenum situations. In cuisine processing, hair nets and sanitation protocols can decrease whilst and how you scan. On energetic construction websites, the last thing you prefer is a tripod within the route of a telehandler.

A pro 3-D Laser Scanning Dallas dealer plans for these realities: prime-visibility stands, clear signage, spotters throughout busy hours, and coordination with facility managers to interchange HVAC modes while fogging or airborne dirt and dust may perhaps intrude with laser returns. We have staged scans at four a.m. in commercial kitchens when surfaces were dry and crews were clean, and now we have used test spheres established to magnetic posts to decrease surface footprint in tight electric rooms. Good archives is safe files.

The authorized and contractual side

On layout-build and CMAR tasks, scanning recurrently lands in a gray house among design responsibility and structure means and programs. Clarify purpose to your contracts. If the experiment is to provide a edition that supersedes current drawings, say so and define the level of element and tolerances. If the scan is for coordination basically, kingdom that certainly and require the trades to check crucial dimensions ahead of fabrication.

Also deal with information possession. Who owns the cloud and brand, and who can depend on them? Owners increasingly prefer the knowledge protected within the turnover, which is cheap, but the settlement should define warranties and obstacles. Scans are snapshots, not promises against future flow or hidden ingredients in the back of walls.

Choosing a 3-d Laser Scanning Service Dallas groups can trust

Dallas has quite a few in a position prone, and a few countrywide corporations that fly in. The properly choice depends to your time table, complexity, and the desire for nearby coordination. Review extra than advertising and marketing brochures. You choose proof of registration excellent, examples of adaptation deliverables similar to your assignment, and a team that is aware creation sequencing in North Texas.

Ask for a sample registration document. Review a RCP slice of a congested space to see if the cloud is sparkling or noisy. Confirm that they're able to align for your regulate and your BIM coordinate machine, not just their own. Most importantly, verify they may meet your turnaround. A quick, suitable test that arrives after the submittal time limit is an steeply-priced memento.

If your mission carries prefabrication, install a workflow with the fabricators previously the experiment. Agree on report codecs, coordinate origins, and naming conventions. That small little bit of governance prevents a variety of friction when the files hits the shop.

Where scanning does not add much

Not each and every circumstance demands a experiment. Simple tenant upgrades with minimal MEP paintings, broad-open tilt-wall shells wherein format is driven by using new format, or in simple terms ornamental improvements can on the whole proceed with common verification. If finances is tight, understand exact scanning of prime-hazard zones other than complete insurance. A targeted half of-day within the riser rooms and above the foremost hall may solve eighty p.c. of the unknowns for 20 % of the price.

Also avoid expectations modest in environments with heavy glass, mirrors, or high-gloss finishes. Most scanners struggle with specular reflections, and you'll want greater care with matte pursuits and oblique angles. In a few situations, a aggregate of entire station pictures and selective scanning is smarter than brute-drive scanning everywhere.

A quick, reasonable playbook

- Define good fortune in measurable terms ahead of the test: which clashes you needs to solution, which elevations count, which tolerances you're going to take delivery of. Tie the test to undertaking keep an eye on and determine alignment with design early, on a monitor share with the design workforce. Model with cause. Include elements that impact fabrication and routing, let the level cloud deliver the rest of the context. Use the information in coordination and design. Do not permit the cloud sit idle on a server. Document decisions and deltas found out from the scan, and proportion them with all trades to avoid fragmented truths.

Stories from the field

At a mid-upward push place of work upkeep close to Victory Park, we scanned a mechanical room scheduled for a new chiller and pumps. The drawings showed a clean direction for piping alongside the east wall. The scan, despite the fact that, printed a subtle tilt in the slab, about 3-quarters of an inch throughout the room. Not catastrophic, but enough to place the pump bases out of allowable level if set up as drawn. The workforce redesigned the house responsibilities pads with tapered grout and have shyed away from a punch-checklist wrestle later while vibration readings came in smooth.

Another challenge, a performing arts venue improve in the Arts District, mandatory a brand new catwalk that threaded among present trusses. Design data have been sparse. The experiment allowed the structural engineer to variation the truss geometry accurately and prefabricate catwalk segments that bolted up with out box welding. The auditorium stayed dark for two weekends, now not two months, and the venue met its reveal calendar.

On a tilt-wall distribution core south of Dallas, the proprietor requested why forklifts kept tripping sensors at one dock door. A quickly experiment of the dock pit and door body confirmed a moderate inward bow of the jamb. The pit’s concrete aspect numerous by means of practically half of an inch over seven toes. The documents explained the false journeys, and the restore was once a centered shim and an adjusted sensor bracket. No want to blame the accessories.

Looking beforehand without the hype

Mobile scanning and SLAM are recovering right now, and they are useful for swift policy cover of intricate interiors. Drone photogrammetry allows with substantial exteriors and stockpiles. But for prime-self belief, tolerance-pushed paintings in Dallas creation, terrestrial laser scanning stays the spine. Its precision, when paired with extraordinary management and careful registration, is not easy to conquer.

If you are weighing when to take advantage of scanning, tie it to milestones: until now fundamental demo to catch hidden services and products, after steel topping out to be sure glide and plumb, formerly MEP tough-in for routing, and pre-pour tests on slabs a good way to host equipment. Those home windows align with decisions that lock in check.

3-d Laser Scanning Dallas contractors and owners place confidence in seriously isn't just a science, it can be a workflow. It starts offevolved with curiosity about in which fact diverges from drawings and ends with fewer surprises, cleanser installs, and a calmer jobsite. Most of the hidden stipulations do no longer desire drama. They want faded, measured in millimeters, captured at the perfect time, and shared with the those who can act on it.